3D surface defect detection

New revolutionary optical technology that can measure the height and depth of surface defects.

• Reliable separation of 3 D defects from 2 D defects.

• Short start up time, no learning phases

• Modular design, no width limitation

• Automatic height adjustment for thick plates

• High resolution

Ideal for final inspection of plates or strips where we can send information to a robot

system that automatically grind off sharp defects.

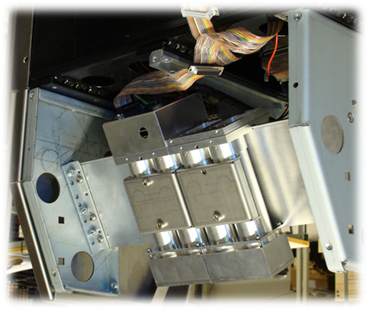

Detmaster MPH – Metal Pinhole Detection System

Detmaster MPH system enables accurate pinhole, hole and edge crack detection as well as an

optional width measurement feature.

The primary advantages of the Detmaster MPH system compared to the traditional pinhole gauges are:

• Measures pinholes from size 10 µm up to large holes with only one measurement system.

• Is able to detect additionally edge cracks from size 200 µm up

• Doesn’t need any mechanical edge following units and edge masks because it includes

active optical edge detection method.

• Ambient light doesn’t interfere to the operation of the Detmaster MPH system because it

includes frequency modulated light sources.

• Includes LED light sources, which have average lifetime of 290 years with constant light

intensity.

• Doesn’t include any component, which needs to be changed frequently. It is practically

maintenance free system.

• Informs the position of each pinhole in MD (machine direction) with an accuracy of 1 mm

and in CD (cross direction) with an accuracy of 8 mm.

• Enables categorisation of different size pinholes, holes and edge cracks to own size

classes. The operator of the Detmaster MPH system may determine the range for each pinhole,

hole and edge crack size class.

• Provides on a graphical user interface a coil report, which indicates location and size

of each individual pinhole, hole and edge crack in a concerned coil.

• Can be pulled out of the line for verification and maintenance purposes with a roll out

system automatically or manually without disturbing running of the process line.

• Comprises dynamic verification tools for easy system performance verification = motor

controlled rotating disc including certified pinhole and hole samples simulating the actual

production line speed.

• Measures optionally the width of the strip with an accuracy of ± 1 mm.

• Measures accurately pinholes with line speeds up to 2000 m/min.

DS25004S MPH-Datasheet 20082008.pdf

http://www.sr-instruments.com/