STRIP SHAPE MEASUREMENT WITH MEASUREMENT ROLL

Shape statistics for the finished

coil: 2-D Perspective graph

Shape statistics for the finished

coil: 3-D graph

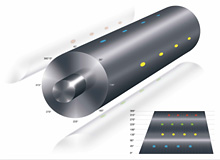

Vollmer shapemeter rolls follow a BFI patent. The massive roll body is equipped with

piezoelectric pressure gauges. The telemetric data transmission and power supply results in

an almost maintenance free operation (no slip rings). The diameter, body length and bearing

of the shapemeter rolls correspond exactly to those of the deflector rolls.

Roll diameters down to 200 mm enable a precise replacement of the deflector rolls in almost

all mills.

The advantages are obvious:

– No additional space required for the shapemeters

– No effects on the strip passline

Stack schedule

While the strip is pulled over the shapemeter rolls, a variety of discreet measurement

zones measures the strip tension distribution. At the same time, the monitor indicates the

desired shape for the current strip. If the mill has the suitable control components, the

shape is controlled in accordance with the requirements of the end customer (refer to Strip

shape control).

An important factor for the design of the shapemeter rolls is the selection of the number

of measurement zones for the rolls. The more measurement zones, the more precise the

detection of the shape profile, but also the more expensive the measurement rolls. Our

experts will be glad to give their advice at any time, based on decades of shape

measurements on running strip material in mills of all types and on strips of all

materials.

Roll surfaces: Steel, chrome, plastics or tungsten carbide

Shapemeter Roll (BFI) – Leaflet for download (German/English)

Planheit_BFI.pdf (544 KB)

Planheit_BFI.pdf (544 KB)

NON-CONTACT MEASUREMENT OF STRIP SHAPE

VIP 08 diagram

Only 200 mm free view onto the strip are sufficient for VIP 08, the optical shapemeter. 200 measurement zones over the strip width offer a brilliant resolution. VIP 08 can be applied with strip tensions of up to 70 N/mm².

Wide range of application:

– Hot rolling mills

– Tension levellers

– Inspection lines

– Shearing lines

– and others

VIP 08 in a pickling line

VIP 08 in a hot mill

Optical Shape Measurement – Leaflet for download (German/English)

VIP08.pdf (371 KB)

VIP08.pdf (371 KB)

STRIP SHAPE CONTROL

On-line measurement

AFC (Automatic Flatness Control)

The AFC works through other mill control components than does the strip thickness control.

With a suitable servohydraulic mill screwdown system that may be retrofit into installed

into older mills and usually exists on new mills, a strip thickness control will achieve

the required results.

The effectiveness of the strip shape control depends largely on the type of control

components that are installed in the mill. The basic control components are: Roll tilting,

roll bending, intermediate roll shifting and zone cooling.

Roll tilting is available in all but certain cluster mills. Not all mills have roll bending

units (positive and negative). The intermediate roll shifting is only available on 6 high

mills and certain special cluster mills. An efficient zone cooling can be added to many 4

high and 6 high mills.

The strip shape control can only use the control components that are installed by the mill,

so that the success of the strip shape control depends on the configuration of the mill.

Vollmer shape controls use all existing control components.

Strip shape measurement with or without control

Even with a limited availability of control components, meaning a limited control

potential, the shape measurement has great advantages for the user. Knowing the current

strip condition enables the adaptation of the rolling conditions to the shape situation. In

the case of poor strip shape, strip breaks can effectively be prevented. In case of strip

with a uniform tension distribution, the mill can be operated with high efficiency. Strip

shape measurement has always resulted in a productivity increase.

Signal Analysis by FFT (Fast Fourier Transformation)

The FFT analysis option offers a product showing recurrent periodical strip thickness

variations both during the strip thickness measurement (on-line, 2D) and after completion

of the coil (off-line, 3D) so that our copper customers, rolling material for the coaxial

cable production, will recognise which coils can be applied for which coaxial cable

standards.

Our steel customers use the FFT instrument for preventive maintenance and fault finding in

the mill (the wave length of the recurrent strip thickness variation indicates which

roller, which roll or which bearing requires maintenance).

FFT Analysis – Leaflet for download

FFT_en.pdf (239 KB)

FFT_en.pdf (239 KB)

SPECIAL MEASUREMENT TASKS

The measurement dimensional factors on strip products is not limited to the measurement of

the strip thickness, strip width and strip shape.

A variety of technical solutions has been developed at our plant due to new challenges by

our customers.

– Curvature measurement,

– Groove measurement on profiled strip,

– Foil sample measurement,

– Cross profile measurement (off-line)

are just some of the many solutions that started as special inquiries and are now well-

tried in the industry.

Such challenges help us to get on and extend our limits continuously and help our customers

find a solution. We appreciate any special measurement task. Please get in touch with us.

VBP Cross Profile Measurement – Leaflet for download (German/English)

VBP.pdf (1.77 MB)

VBP.pdf (1.77 MB)