Hydraulic screw down systems

The upgrade of mills by Vollmer not only includes the addition of up-to-date measurement technology, but also includes the complete design, manufacture and installation of servo hydraulic hydraulic screwdown controls.

The condition for a high speed strip thickness control is the fast and precise screwdown of the rolls. Fast means just a few milliseconds and precise means an accuracy of less than a µm.

Vollmer has the experience of decades in replacing spindle-motor screw downs in existing mills with servo hydraulic mill screw down, in designing the new cylinders per the space in the mill, in designing and planning all hydraulic power units and in modifying the mill on site (anywhere in the world).

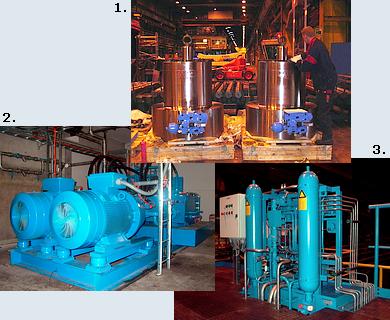

1. The new cylinders are unpacked

2. Hydraulic power unit, 2 pumps on a motor shaft

3. Valve stand on the mill

The efficiency of the servohydraulic mill screwdown is the necessary basis for the success of the high speed strip thickness control.

The hydraulic cylinders must move to the nominal position with a sufficiently low friction and highest speed (3 mm/sec). The position is controlled by high-resolution position sensors (0,2 µm).