CONTACT STRIP THICKNESS MEASUREMENT

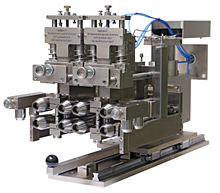

Gauge for medium and wide strip mills, highest measurement accuracy with thicknesses up to 22 mm

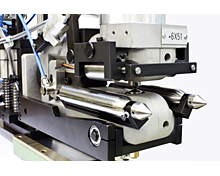

Gauge for rod stock

Detail view of a gauge for medium and wide strip mills

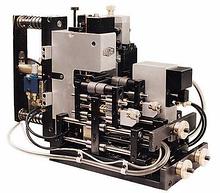

Gauge for narrow strip mills, highest measurement accuracy with thicknesses down to 0,01 mm

Basic Principle

Either inductive or digital transducers or measurement rolls contact the strip surface from above and below at opposite positions. The evaluation of the differential signal results in the strip thickness.

Specific devices of the gauge head (such as the unique rotational suspension, heater, cooling system, etc.) ensure that the measurement is always perpendicular to the material regardless of the strip conditions, such as waviness, vibrations etc., and that effects, such as the strip temperature etc., can be compensated.

Resulting in many different gauge designs, the different strip dimensions, speeds and environments require accordingly adapted gauges

Gauge for slitting lines or tube welding lines, for example, very robust

Advantages

Absolute measurement of the strip thickness, independent of alloys, easy maintenance, inexpensive spare parts.

If classic inductive transducers are applied, the differential signal is evaluated by measurement amplifiers.

The signals of the digital transducers are evaluated by the VTS (Vollmer Touch Screen).

VTS (Chinese)

VTS (Chinese)

VTS

VTS is applied if Vollmer contact gauges are not equipped with analog transducers, as usual in the last decades, but with digital transducers. The amplifier (VMF) is replaced by VTS. The main advantage of the digital transducers is the large measurement stroke, allowing to measure very thick strip material without providing a manual or motor transducer adjustment.

VTS is an evaluation unit with touchscreen, processing up to four measurement parameters. The plain text displays, available in numerous languages, allow easy operation. Color changes of the display in case of tolerance exceeding and many other features make VTS a very attractive solution. It is often possible to modify old contact gauges to digital transducers and VTS. Must be checked in each individual case.

VUD Strip Thickness Measurement – Leaflet for download (German/English)

VUD.pdf (1.07 MB)

VUD.pdf (1.07 MB)

Combined strip thickness and strip width gauge in operation

Width and thickness gauge combination

The contact strip width gauge is usually installed in combination with a contact strip thickness gauge. Transducers touch the strip edge on both sides, the evaluation of the differential signal results in the strip width. The basic difference to the measurement of the strip thickness is the design of the diamond contacts as oblong shapes (blades), preventing the transducer from slipping off the edge in case of unsteady strip run. Contact measurement is unbeatable in the case of very oily strip or mill mists.

VBK/VABL on Narrow Strip / Profile – Leaflet for download (German/English)

VBK-VABL (2 MB)

VBK-VABL (2 MB)